Differences Between Acrylic and Polyurethane Sealants: A Comprehensive Comparison

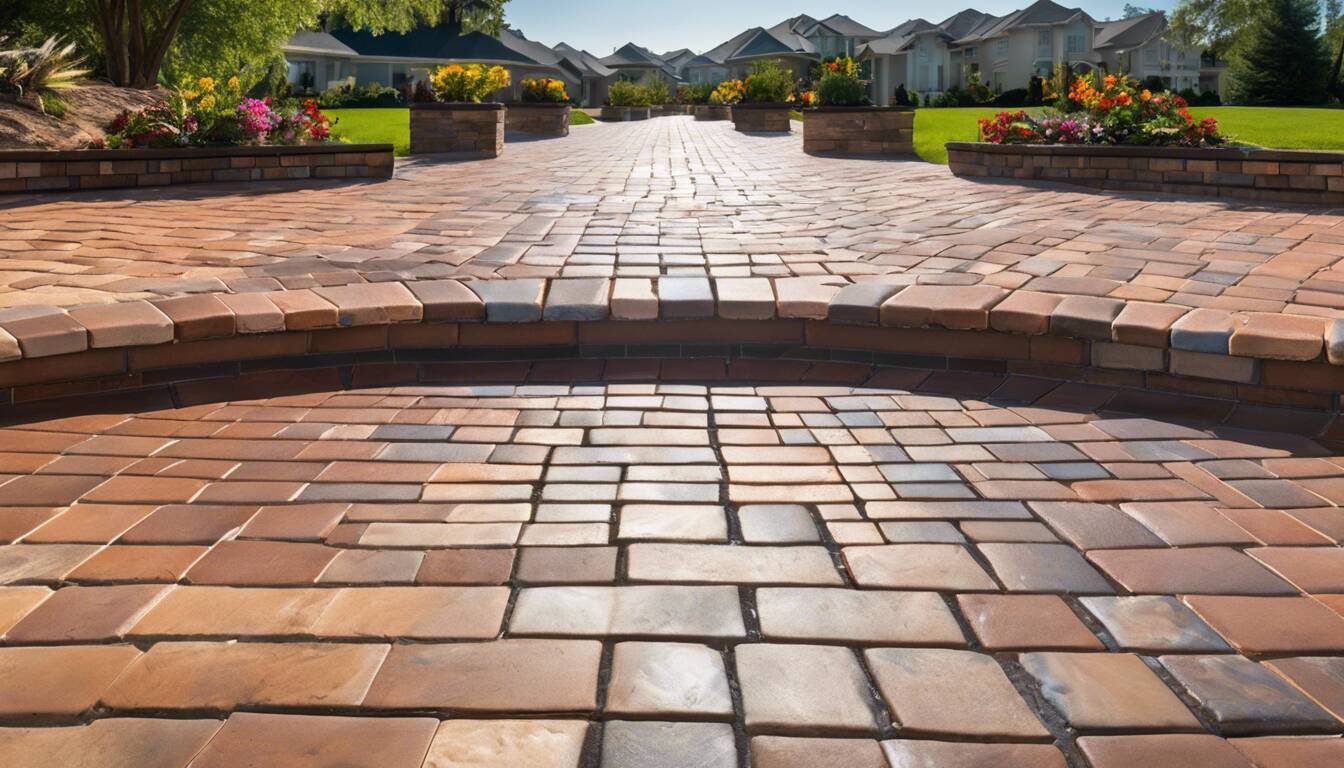

Choosing between acrylic and polyurethane sealants often puzzles homeowners looking to protect their paver stones effectively. Many dive into DIY home improvement projects only to find themselves at crossroads, wondering which option promises more durability and less maintenance hassle over time. You are not alone; many face this same challenge when considering these key materials.

In this comprehensive comparison, grounded in meticulous research and expert insights, we will explore the unique characteristics of each sealant type. Our findings dig deep into practical experiences, revealing how quick drying times and long-term resilience play critical roles in determining the best choice for any project—whether it's enhancing your driveway's longevity or ensuring the seamless appearance of your garden paths.

The primary difference between acrylic and polyurethane sealants lies in their composition and properties; acrylic is water-based and dries quickly, making it suitable for projects requiring rapid completion, while polyurethane is often solvent-based, offering superior durability and wear resistance but requiring longer curing times. Additionally, polyurethane provides better slip resistance and customizable finishes compared to the more limited options of acrylic sealants.

Overview of Acrylic and Polyurethane Sealants

Acrylic and polyurethane sealants serve various applications, with each offering unique advantages determined by their chemical compositions.

Acrylic sealants are primarily water-based, which not only makes them user-friendly but also highlights their quick drying capabilities. As a result, they form a flexible seal ideal for projects that require fast completion. This flexibility is essential for indoor tasks where temperature fluctuations are minimal. However, while easy to apply, they do not possess the same durability as their polyurethane counterparts.

On the flip side, polyurethane sealants stand out due to their solvent-based nature, providing a formidable alternative for demanding conditions. They cure into a robust, elastic seal that excels in outdoor environments where exposure to moisture and UV light is a concern. Their superior adhesion properties make them exceptionally suited for heavy-duty applications, such as in paver joints and other structures exposed to significant wear. This inherent durability comes at a cost; polyurethane options typically require longer curing times compared to the quicker setting of acrylic seals.

Choosing the right sealant ultimately hinges on understanding your specific needs—whether you prioritize drying time or durability is crucial in making an informed decision.

Key Characteristics of Acrylic Sealants

Acrylic sealants offer a softer and more flexible seal that performs best in relatively stable indoor conditions. Their design allows for easy application, rapid drying, and painting directly over once dry—perfect for fine finishes in home improvements and repairs. Imagine applying an acrylic sealant around windows or door frames where you want nothing more than a quick fix that will look good immediately without requiring excessive waiting.

Key Characteristics of Polyurethane Sealants

In contrast, polyurethane sealants deliver performance through toughness. They create a strong, elastic bond that withstands mechanical stress and environmental challenges. Ideal for exterior applications, these sealants prevent wear caused by elements like rain or shifting soil beneath pavers. This results in longevity and minimal maintenance over time; think of them as investing upfront for security later on.

Understanding these foundational differences sets the stage for further exploration of how these sealants measure up in terms of durability and flexibility in various settings.

Durability and Flexibility Comparison

The resilience of a sealant can often make or break a project. This means that when we discuss durability, we're looking at how well a sealant can stand up to wear and tear over time. Polyurethane sealants shine brightly in this category, boasting impressive longevity. Their robust nature allows them to endure heavy traffic and mechanical stresses without succumbing to damage, which is why they are preferred in spaces like driveways and industrial settings.

According to industry standards, polyurethane sealants typically last 10-15 years, even under strenuous conditions, while acrylics may require reapplication every 2-5 years in high-traffic areas. This makes polyurethane not only a stronger option but also an economically sound investment for those seeking low-maintenance solutions.

However, it’s worth noting that this durability comes at a price. The initial cost of polyurethane sealants can be significantly higher than that of acrylics, which may turn some budget-conscious consumers away. Still, when businesses make the choice to invest in polyurethane for environments subject to heavy use—like warehouse floors—they often find that the lower frequency of repairs compensates for the upfront expense.

As we shift our focus from durability to flexibility, a different picture emerges.

Flexibility

When it comes to flexibility, acrylic sealants have the upper hand. Their ability to expand and contract allows them to adapt seamlessly to minor movements or vibrations in structures without cracking. This characteristic proves particularly advantageous for indoor applications where conditions can fluctuate throughout the year. For instance, temperature changes can impose stress on window trims; one homeowner noted how their acrylic sealant effectively maintained its integrity through seasonal shifts without showing any signs of cracks—a testament to its adaptability.

While both types of sealants have their merits in terms of flexibility and durability, it becomes clear that the right choice depends on the specific application at hand. In cases where movement is anticipated—think flooring or joints in walls—acrylic might just be your best bet. However, for more permanent installations where longevity is paramount, polyurethanes probably warrant consideration despite their costlier sticker price.

Moving forward, it's crucial to evaluate these sealants based on how well they adhere and bond, as these properties will directly impact their overall effectiveness in any given application.

Adhesion and Bond Strength

Adhesion refers to a sealant's ability to stick to the surface onto which it is applied, while bond strength describes how well a sealant can hold two surfaces together when stress is applied.

When we look at polyurethane sealants, they truly shine in both categories. Their robust chemical composition allows for superior bonding, making them ideal for demanding environments. This is why contractors often rely on polyurethane sealants for outdoor concrete repairs or heavy-duty applications. For instance, sealing paver joints with polyurethane ensures that the bonds formed can handle significant foot and vehicle traffic without compromising integrity.

Similarly, think of a well-built bridge. The stronger the materials used in its construction, the better it will perform under pressure—this is precisely how polyurethane behaves when tasked with tough jobs.

However, that doesn’t mean acrylic sealants are not valuable; they simply serve a different purpose and excel in particular areas where high performance isn’t as critical.

Acrylic sealants are known for their excellent adhesion to porous surfaces like wood and masonry. They offer practical choices for less intense applications, such as interior connections involving baseboards or crown molding. One notable advantage of acrylics is their paintable surface after application, which makes them highly beneficial for projects where aesthetics are paramount. Imagine touching up your freshly painted room without worrying about unsightly seams; this flexibility makes acrylic a go-to choice for home-improvement enthusiasts.

-

Porous Surfaces: Acrylic can naturally adhere well to materials such as wood and masonry.

-

Interior Use: Interior connections benefit from acrylic’s easy application.

-

Aesthetic Projects: The ability to paint over acrylic facilitates seamless integration into finished interiors.

Understanding these differences prepares you to choose the right sealant tailored to your needs, leading us directly into exploring compatibility across various surfaces and their ideal uses.

Surface Compatibility and Ideal Applications

Polyurethane sealants stand out for their remarkable adhesion to various surfaces, making them a top choice for many applications. They adhere effectively to materials such as concrete, metal, and plastic, which expands their utility across different settings. Imagine a construction or renovation scenario where the durability and strength of the seal are paramount; in such cases, polyurethane's versatile bonding capabilities are invaluable.

However, it's essential to note that this beneficial trait comes with caveats: polyurethane can react negatively with specific materials like rubber or tar. Over time, this reaction may lead to degradation of both the sealant and the surface it’s applied to.

A valuable strategy here is to always conduct a preliminary test on a small section of the surface with a polyurethane patch. This simple step can save you from facing significant material incompatibility issues later on.

Shifting focus, acrylic sealants present a slightly different profile in terms of surface compatibility yet maintain unique advantages tailored for particular applications.

Ideal Applications

While acrylic sealants may not boast the same level of adhesion strength as their polyurethane counterparts, they shine in scenarios requiring quick drying times and easy paintability. This makes them an excellent choice for interior projects where expediency is desired. For instance, picture yourself working on drywall and wood trim—these materials not only require a sealant that adheres well but also one that dries quickly so that subsequent painting can occur without delay.

In settings like kitchens or bathrooms, where moisture resistance is crucial, acrylic sealants excel by sealing fixtures efficiently while allowing surfaces to breathe.

The beauty of acrylic lies in its ability to provide sufficient moisture protection without the mechanical strength needed for high-stress environments. In practical terms, you could use acrylic sealants to neatly finish edges around sinks or bathtubs, creating a clean boundary that keeps water at bay without risking the adhesive bond breaking down under pressure.

With a clearer understanding of how surface compatibility influences your choice of sealant, let's examine how these products fare in different environmental conditions and what that means for your specific applications.

Environmental and Weather Resistance

When discussing environmental resistance, it's essential to understand its role in how long a sealant will last and how effective it is in various outdoor conditions. Polyurethane sealants excel due to their remarkable resistance to UV radiation, moisture, and temperature fluctuations. This resilience makes them the go-to choice for many outdoor projects that need to withstand the elements over an extended period.

In my experience, using polyurethanes on exterior applications has often resulted in significantly prolonged durability—important whether you're sealing pavers, wooden structures, or any other outdoor materials.

Research shows that polyurethane sealants maintain their integrity and flexibility even after years of exposure to direct sunlight, humidity, and extreme temperature changes. This is particularly helpful in regions with drastic seasonal changes where temperatures can swing from icy cold to scorching heat within a short time frame.

While polyurethane offers robust performance outdoors, the story shifts when we consider acrylic sealants.

Acrylic sealants provide some level of weather resistance but typically cannot match the durability offered by polyurethane counterparts. They perform well under less demanding situations, making them suitable for indoor applications or areas with moderate exposure to outdoor conditions. However, they may show signs of wear more quickly when exposed to harsh weather such as heavy rain or high UV radiation.

The environmental impact also plays a critical role in choosing between these two types of sealants. Acrylic sealants tend to be water-based, which makes them a friendlier option for people concerned about eco-friendliness. They are often recommended for indoor projects when lower VOC (volatile organic compounds) emissions are needed. This quality positively impacts air quality and aligns well with sustainable building practices.

I've found that using acrylics indoors helps reduce potential pollutants in enclosed spaces, thus promoting healthier living environments.

Understanding the nuances between these sealants sets the stage for making informed choices that meet your specific project needs effectively.

Choosing the Right Sealant for Your Project

Making an informed decision requires a thoughtful approach that aligns your specific needs with the characteristics of the available products. Begin by identifying the particular requirements of your project. Ask yourself if the sealant will be applied indoors or outdoors, as this distinction significantly influences its performance and longevity.

For instance, outdoor sealants face harsher environmental conditions which require robust resistance to weathering, UV exposure, and moisture. Meanwhile, indoor applications may prioritize quicker drying times and minimal odor during installation.

Once you have these requirements in hand, the next crucial step is to assess how much mechanical stress the sealant will need to endure over its lifetime.

Step 1: Identify Project Requirements

Understanding the environment where your sealant will be used not only helps in selecting between acrylic and polyurethane but also involves considering material compatibility. Some materials may require sealants with special properties to ensure adhesion and durability.

Take a few moments to sketch out what elements will impact your sealant choice in terms of location, application method, and anticipated wear.

After clarifying your project's requirements, it’s time to examine how much wear and tear the sealant may experience.

Step 2: Assess Stress Tolerance

Understanding the level of mechanical stress that the sealant will encounter is critical. High-traffic areas or surfaces exposed to heavy loads will demand products that can withstand significant wear without degrading.

Additionally, contemplate future maintenance work; some sealants might require reapplication sooner than others based on their durability and the conditions they're exposed to.

As you gauge potential stresses, don't overlook the financial aspects and environmental factors involved in your choice.

Step 3: Budget and Environmental Considerations

Aligning your budget with the upfront costs of each product is essential, but it’s equally important to factor in long-term maintenance implications as well.

For instance, while polyurethane sealants may have a higher initial cost, they tend to last longer—this means you might save money in the long run by not needing to replace them frequently. Moreover, consider environmental impacts; many modern consumers are increasingly concerned about lower volatile organic compound (VOC) emissions due to health regulations or personal preferences.

Therefore, reviewing product specifications not only for price but for their environmental safety ratings can highlight options that meet regulatory compliance.

| Factor | Acrylic Sealant | Polyurethane Sealant |

|---|---|---|

| Drying Time | Generally within 1 hour | 4-8 hours |

| Durability | 2-5 years typical usage | 10-15 years in heavy use |

| Ideal Applications | Indoor fixtures | Outdoor paving and structures |

| Environmental Safety | Lower VOC emissions | Higher VOC emissions |

| Flexibility | High | Moderate |

Still unsure about which sealant best suits your needs? Don't hesitate to consult with us at AZ Clean and Seal for expert advice tailored specifically to your project requirements.

In summary, understanding these key factors will enable you to make informed choices when selecting between acrylic and polyurethane sealants for your specific project needs. Evaluating your requirements thoroughly sets you up for success in achieving effective results.